Discover our latest brochures!

Our new range of brochures are now available to download, offering a comprehensive look at our full product line and capabilities.

Our self-supporting Skyline Box, Skyline and Heritage Skylights are available in several formats, including hipped, gable and polygonal designs. Additionally, these skylights feature optional glazed vertical upstand frames, which allow you to create an elegant ‘Lantern’-style skylight.

Our skylights feature structural aluminium ridge, hip, and cill members, ensuring robust and durable construction. They attach securely to a properly weathered and finished flat-topped structural upstand curb. The finished curb must be at least 100mm wide to accommodate our cill member. We manufacture skylights in 5° increments from 15° to 45° pitch, catering to a wide range of architectural requirements. Additionally, we offer skylights in widths ranging from 1500mm to 6000mm. They can also be supplied in any length required. This provides excellent flexibility for a variety of project specifications.

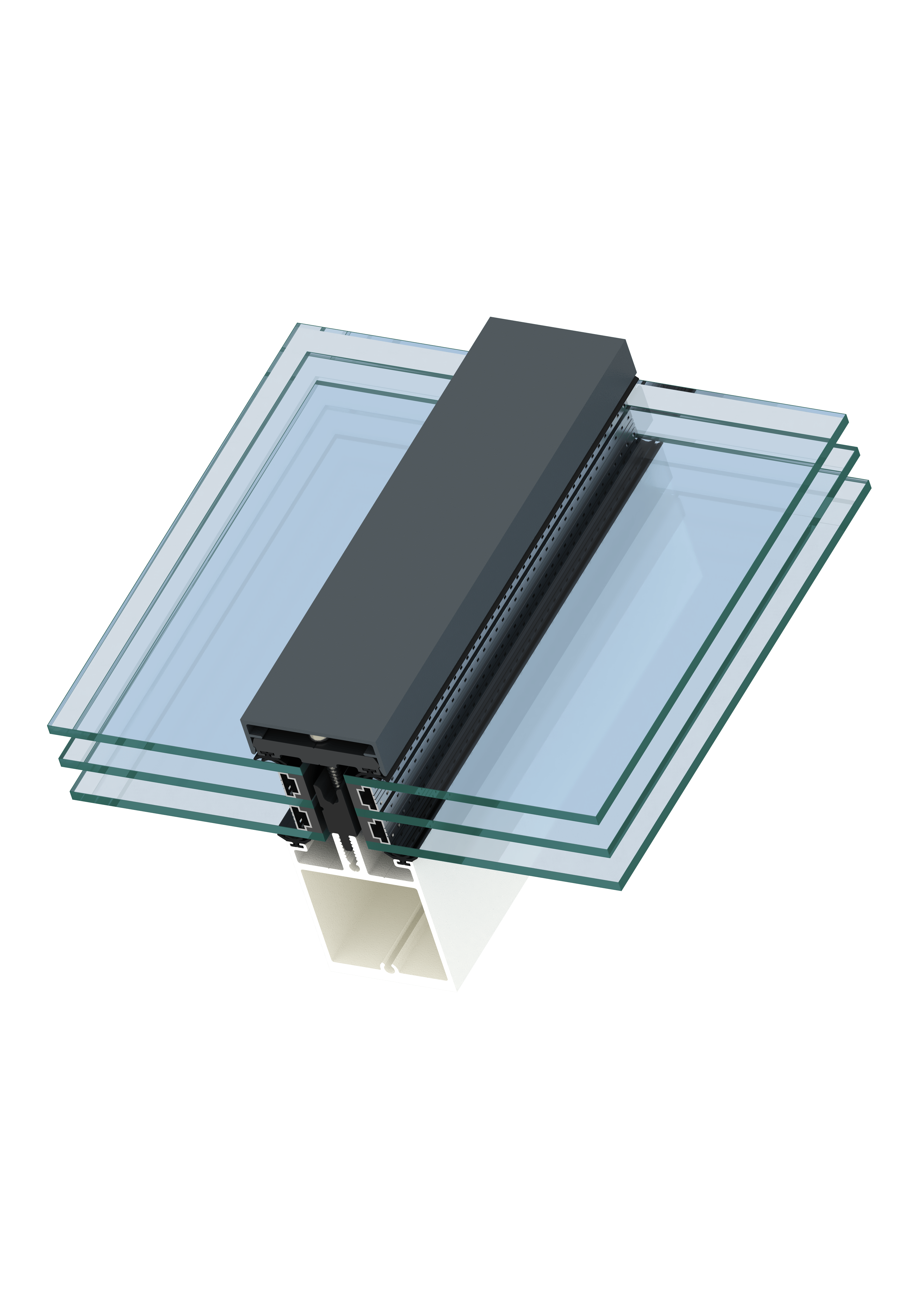

Our custom skylights are compatible with single, double and triple-glazed applications, enhancing their versatility. They are available at multiple pitches and configurations, making them one of the most adaptable self-supporting systems on the market. Whether for residential or commercial projects, our custom skylights deliver exceptional performance, aesthetic appeal and adaptability, meeting the diverse needs of modern architecture.

Our self supporting skylights are a versatile range available incorporating our Skyline Box, Skyline and Heritage type patent glazing bars.

They are mostly supplied in a double glazed format but are also available in single and triple glazed formats to suit your requirements.

Our skylights are compatible with single, double and triple-glazed applications, making them one of the most versatile self-supporting systems on the market.

The Main Contractor provides the structural kerbs to which our skylights attach. The structural engineer should design these kerbs to withstand all lateral loadings imposed by the skylight. These loadings vary depending on pitch and span, so the engineer must calculate them accurately.

If the kerbs have insufficient strength to resist ‘spreading’, which is usually the case, then the use of our integral stainless steel tie wires at approx. 3 metre centres along the ridge line becomes a requirement to prevent any spreading of the structural kerbs.

Our new range of brochures are now available to download, offering a comprehensive look at our full product line and capabilities.

Click the links below to view our 2D drawings, 3D renders, H10 Specifications and Brochure to help you develop and visualise your roof glazing project.