Discover our latest brochures!

Our new range of brochures are now available to download, offering a comprehensive look at our full product line and capabilities.

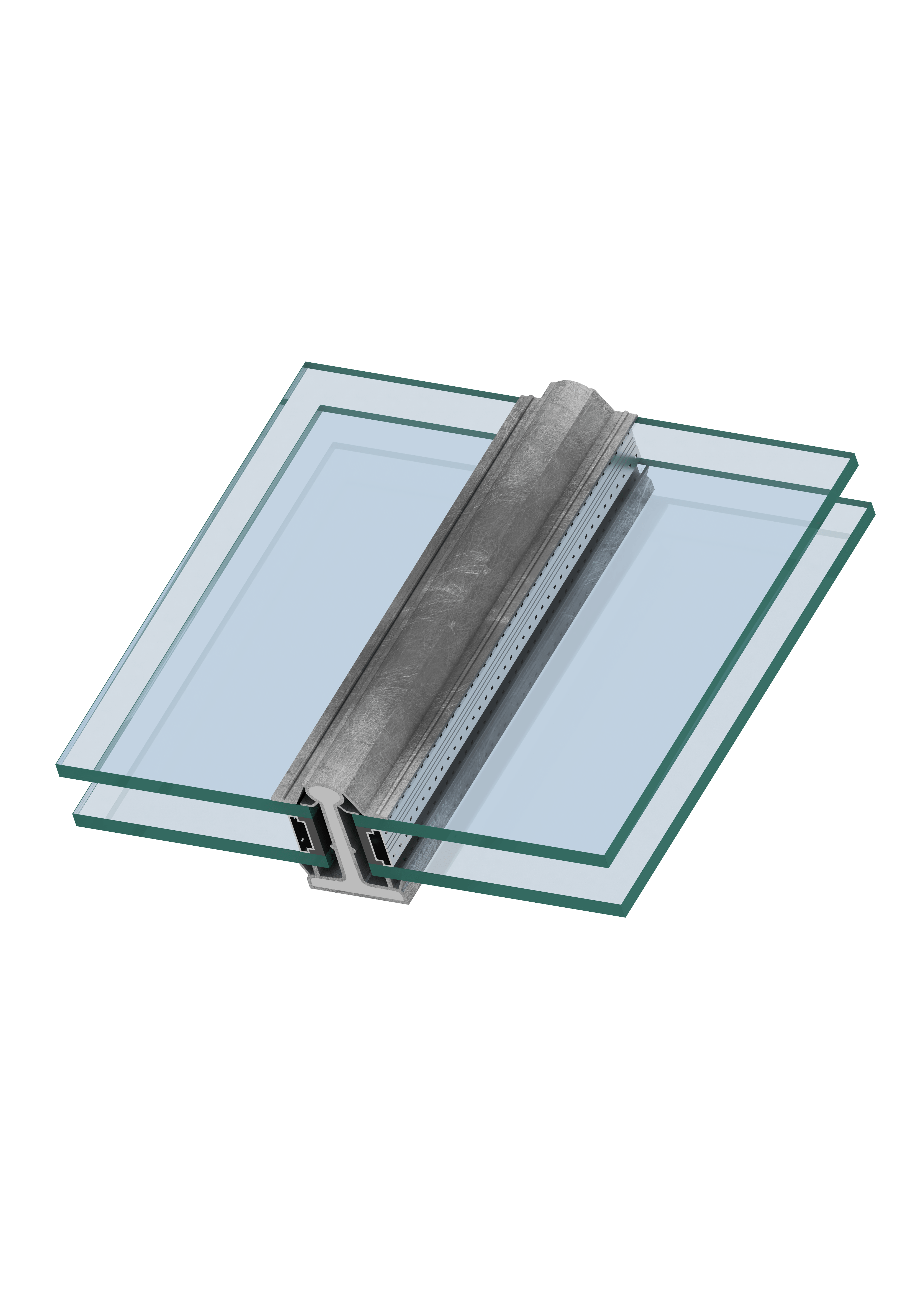

Heritage Glazing Bars for glass roofs

Our Heritage glazing bars are a truly distinctive solution for glass roof systems in historic and listed buildings. Heritage glazing refers to specialised roof glazing systems that preserve traditional aesthetics while providing modern structural performance and energy efficiency.

Manufactured from lead-covered steel and based on original Victorian-era specifications, these systems combine historical authenticity with modern engineering standards, making them ideal for listed buildings, conservation projects and prestige new developments seeking period accuracy.

No other product on the market matches the heritage integrity and visual authenticity of our leaded heritage double glazing bar system. Designed for both listed properties and high-end contemporary projects, they provide the perfect balance of aesthetic tradition, durability and thermal performance.

Whether you’re restoring a Grade I or Grade II listed structure or recreating a traditional glass roof design for a new build, our heritage glazing bars for glass roofs offer the strength, longevity and craftsmanship your project deserves.

Each metal glazing bar features a galvanised mild steel core, encased in a seamless lead extrusion and protected by a twin-wing weathering system. This unique construction provides superior strength and minimises heat loss – even when used with double-glazed or triple-glazed roof units.

Our Heritage leaded steel glazing bars are a unique system, combining the strength of metal glazing bars with the authenticity of Victorian design. Featuring a galvanised steel core and seamless lead extrusion, the glazing bar includes a twin-wing weathering system, hermetically sealed lead ends and cast brass fixings.

Designed for roof glazing applications, these bars meet BS5516:2004 standards for both sloped and vertical installations. They are ideal for use with glass or polycarbonate infill panels, and compatible with single, double or triple glazed units, including leaded heritage double glazing.

Whether you’re restoring a Grade 1 or Grade 2 listed building or creating a traditional-style roof on a new project, our Heritage glazing bars for glass roofs deliver performance and historical accuracy.

Unlike aluminium alternatives, the Heritage bar typically weighs more than twice as much, providing both durability and structural rigidity. Despite this, Heritage glazing bar costs are comparable to modern powder-coated systems like our Skyline SPG7.

Produced in-house using the original heavy-duty rolling equipment, each bar is engineered for long-lasting performance and is suitable for conservatory roofs, canopies and bespoke architectural glazing.

This solution supports a full range of glazing options, with superior thermal properties to reduce heat loss — making it an increasingly popular choice for clients seeking energy-efficient heritage-style glazing systems.

Our new range of brochures are now available to download, offering a comprehensive look at our full product line and capabilities.

Performance Data for Heritage patent glazing bars

The glazing bar spans shown above are based on using 6mm thick glass for the double glazed, single glazed and canopy types, and the bars being spaced at 600mm centres. We will select the appropriate glazing bar for each contract. Spans are dependent upon the site location and exposure rating, site altitude, distance from the sea, height of glazing from ground level, shape of the roof, pitch of glazing, glazing bar centres, glass weight, wind speeds, snow load, dead load and maintenance loads.

* The above spans for each glazing bar have two values. The lower span values are calculated using the most extreme environmental loadings possible in the UK whereas the higher span values are based on the least extreme. Due to the wide range of these values it is therefore essential that we are supplied with the site postal code to enable us to calculate the correct glazing bar type for every project. There are a large number of variables which are used to determine the maximum span of the glazing bars so please do not attempt to buy any glazing bar materials from us without first allowing us to carry out the necessary calculations for your project.

Click the links below to view our 2D drawings, 3D renders, H10 Specifications and Brochure to help you develop and visualise your roof glazing project.

Heritage double glazing is a window or roof glazing system designed for historic and listed buildings. It combines traditional aesthetics, such as leaded bars, with modern thermal performance, offering single, double or triple glazed options for rooflights, canopies and walkways.

Heritage glass refers to glass used in conservation projects or historic buildings that replicates traditional Victorian or Edwardian glass styles. It maintains the visual character of original structures while meeting modern performance standards.

Heritage glazing bars are ideal for listed buildings, historic restorations, and prestige new builds that require traditional-style glazing. They can also be used in contemporary projects that want to replicate Victorian aesthetics.

Yes, they are designed to work with single, double or triple glazed units and include a twin-wing weathering system, reducing heat loss while retaining heritage authenticity.